News

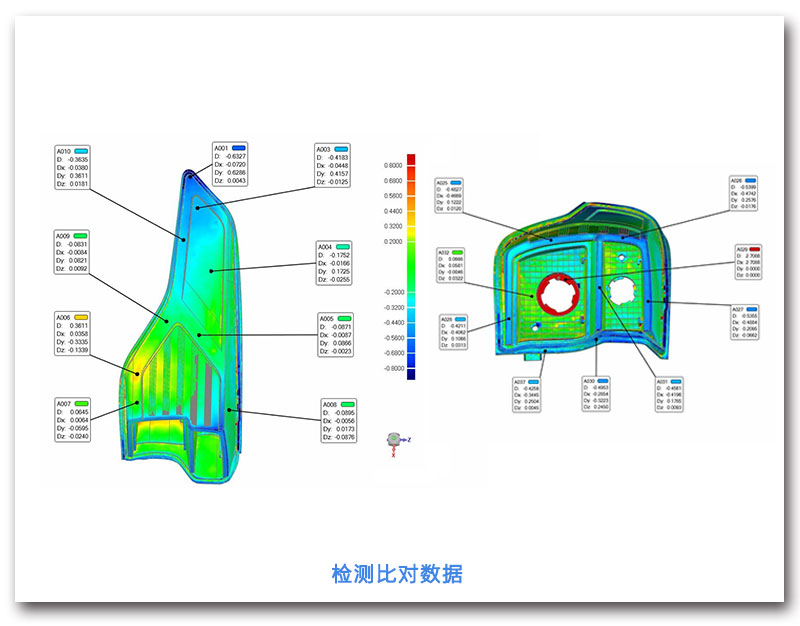

The headlight would appear gap during assemble after injecting. The personnel can’t locate the deformation place and its data.

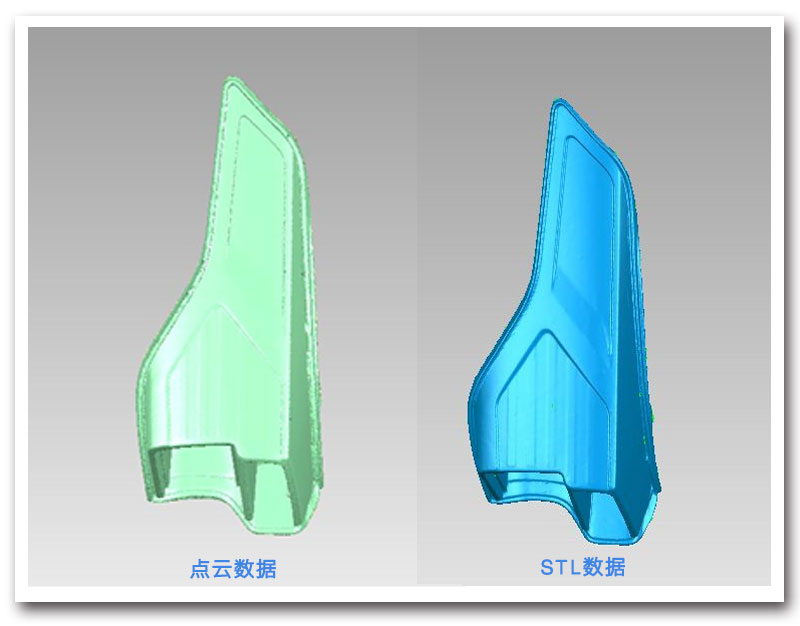

STEP1.Using hand held scanner to scan the light and obtain 3d data

STEP2.Do the comparison to its model file

STEP3.Analyze the deviation

STEP4.Adjust the product

Totally 10minutes for post mark points, scanning and data processing

What about the result?

The light fitting can be held on the hand during scanning

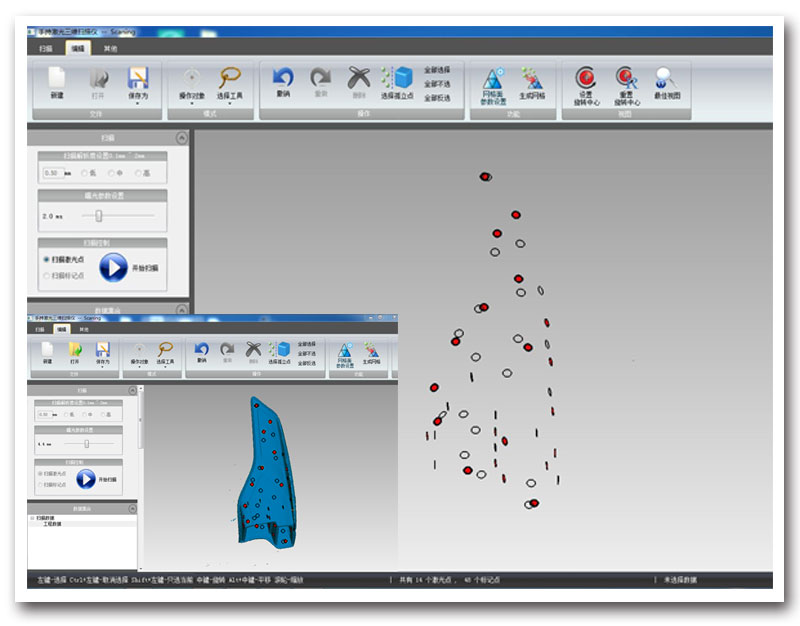

scanning interface & mark points

mark point cloud & mesh

Summary

HSCAN 3d scanner can scan from multi angle and it decrease the death angle. It can keep the data complete. The output format is compatible to many 3d software. Customer consider the scanner as an important tool during product design and detect, it also provide data support for product develop and quality assurance.

HSCAN331

HSCAN331