News

- Turbine blade 3d detect by HSCAN 3d scanner

- Ediator:Hangzhou Scantech Co., Ltd.Date:2017-02-22 14:44 Click:

Turbine is the fan in the automobile or aircraft engine, it use the exhaust gas to blow the fuel stem into engine to enhance engine performance. It is a main part of aircraft engine, gas turbine and steam turbine.

The customer got an offer which need to write a test report. However, the tradition test way is inefficiency and it seriously affect the manufacturing productivity. And the product can’t be exported to overseas.

1.Large number of turbine blades, and the tradition measurement cannot be fast detection.

2.The blade has many death angle and lead to the incomplete data acquisition, and can’t do the 3d detect.

After understanding the high performance and the features of high accuracy of HSCAN 3d scanner, they attempts to use HSCAN 3d scanner to obtain blade’s 3d data, and achieve the quality inspection of turbine blade, thereby significantly improving efficiency.

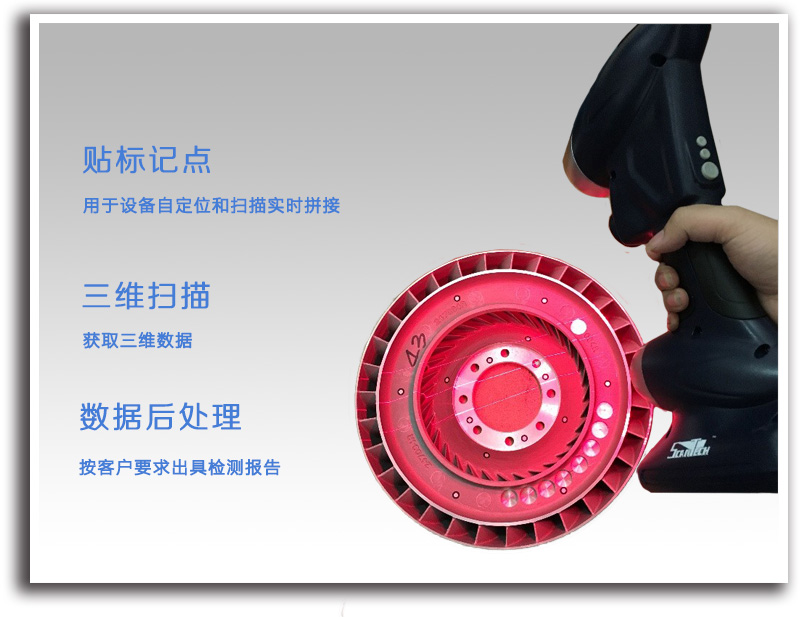

STEP1.Using HSCAN 3d scanner to obtain the turbine’s 3d data

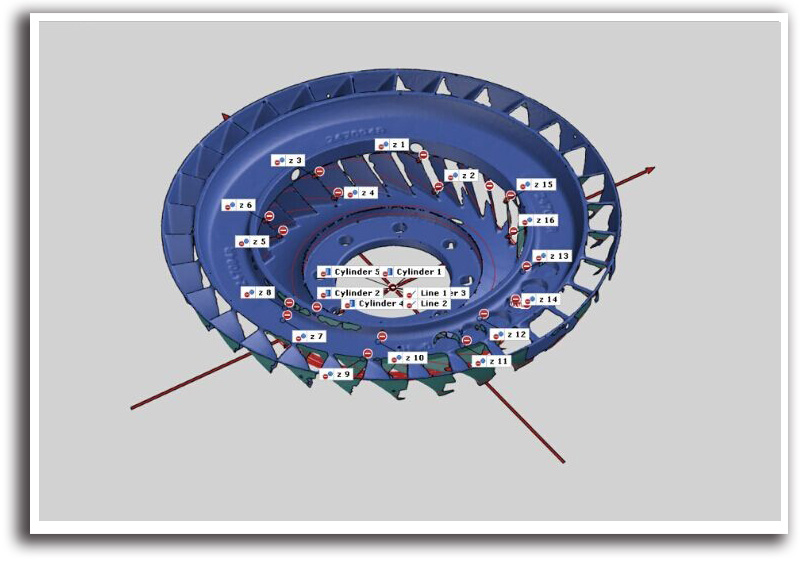

STEP2.Do the comparison to its model file

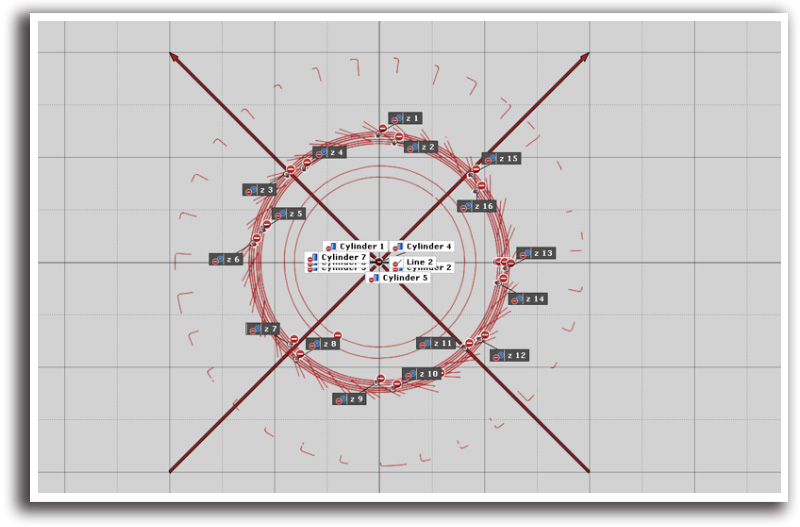

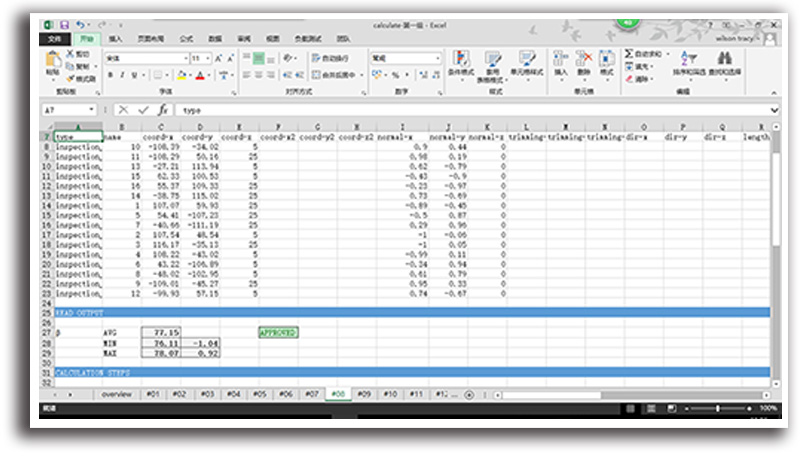

STEP3.Analyze the deviation

STEP4.Adjust the product

「No powder, Highly scan speed, Highly efficiency」

「High accuracy, Small death angle, Easy to operate」

What about the result?

Fitting features, get the section

Extract testing element according to customer’s demand

Provide test result according to customer’s demand

Summary

HSCAN 3d scanner can scan from multi angle and it decrease the death angle. It can keep the data complete. The output format is compatible to many 3d software. Customer consider the scanner as an important tool during product design and detect, it also provide data support for product develop and quality assurance.

HSCAN331

HSCAN331