Aviation is a high technology industry; it is the engine of the national advanced technology develop. Even a minor error may make irreparable loss, therefor, the quality must be control strictly. 3 d measurement technology has a broad application prospect in the field of aviation navigation, can offer a variety of solutions for industry development and progress.

一、Detection

Most tradition way of detecting adopts contact way to do the detect, such as use the clamp fixture, which has high accuracy but low efficiency. What’s more, it may damage the objects.

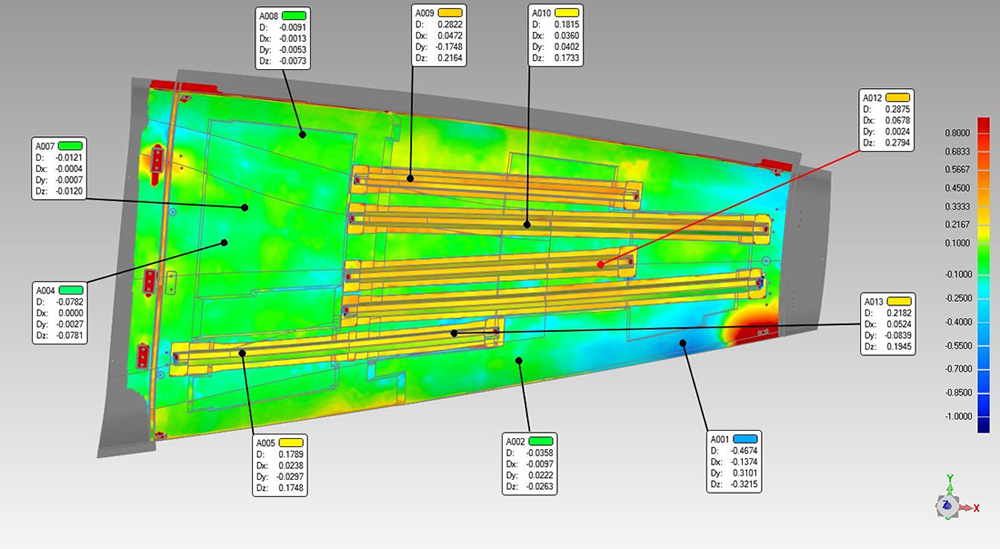

The HSCAN and ZSCAN optical measurement equipment, Using optical principle for surveying and mapping. Provide reliable 3d data on the premise of no damage of scanned object. And the scanning is not restricted by the size of the object. Corporate with the MSCAN can sharply reduce the cumulative error of large objects. Comparing the 3d data to 3d drawings, can obtain the deviation of the objects, which provide basis of the later develop. The convenient scan also greatly improves the efficiency of detection, reducing time and manpower cost.

二、Modeling design

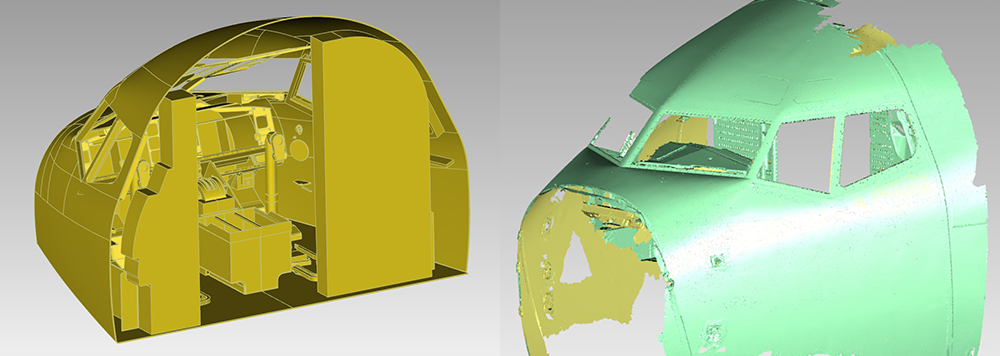

3d scan can also be used in the mechanical reversal design. Obtain the contour data and do the analyze, reverse design the product drawings for processing. Structure compound can be achieved through the reverse modeling, which have important implications in data save and technology innovations.

三、Wear analyze

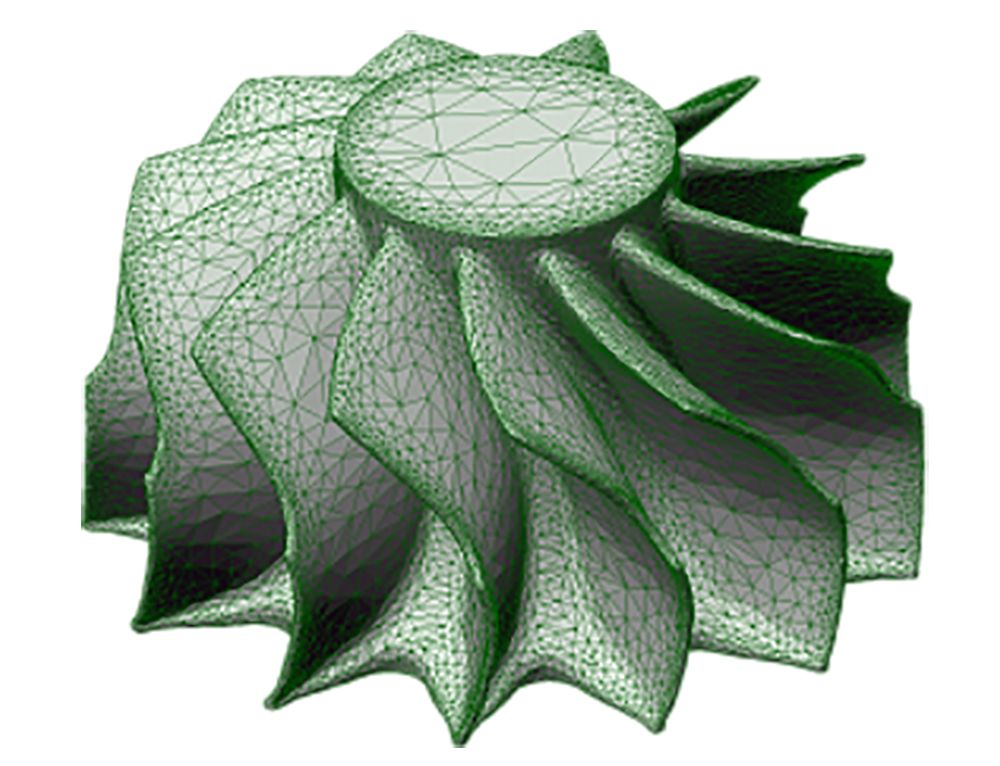

3d scanner can obtain 3 d data before and after use. And the deformation degree can be obtained after analyze the data, which provide the technical support for the improve and strengthen. At the same time, high precision scan can also found damaged parts, provide data basis for maintenance accurately and timely.

【ASK QUESTION】