News

With the popularization of vehicles, vehicle parts are in large demand. Wheel hub also became the selling products in converted stores. Car wheels are an important part of auto parts, along with the growth of China's auto parts industry, wheel hub industry has grown up.

Car detection before the wheel mold would be moving in the laboratory by using the contact type coordinate three RBI detection, the environmental requirements are harsh, point measurement is slow, low efficiency and high cost of equipment, the measuring head due to contact force caused by wear, in order to maintain a certain precision, often need correction probe.

Traditional methods has relatively harsh requirements to environmental. Point-by-point measurement, slow, inefficient, and the high cost of equipment and the measuring head easy to wear due to contact force, in order to maintain a certain degree of accuracy, the probe need to be frequent calibrate.

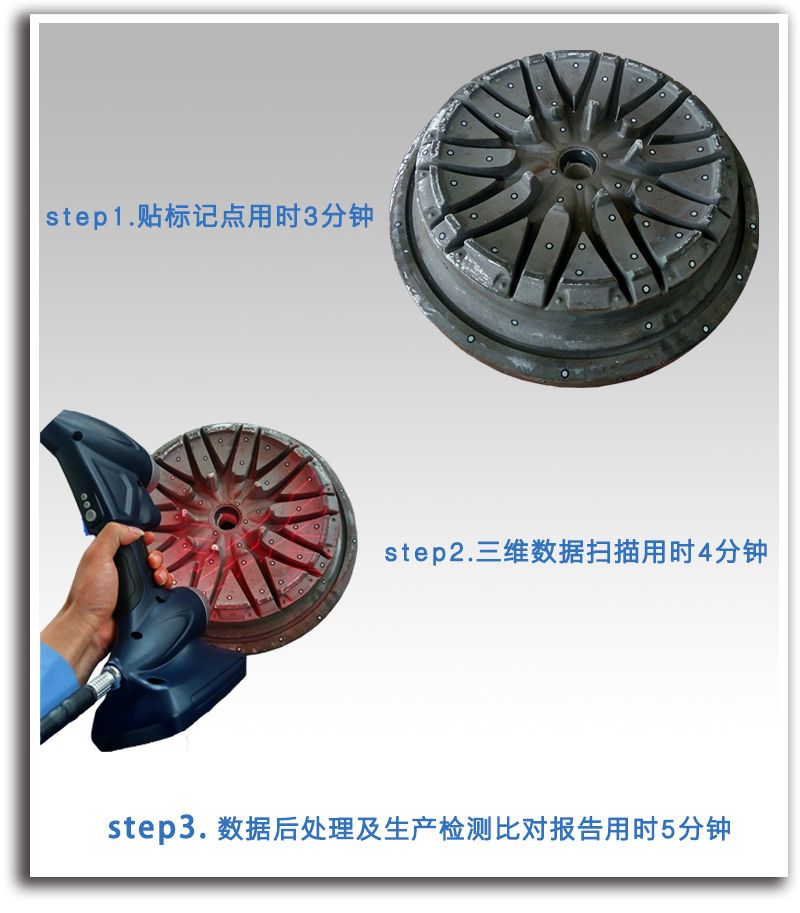

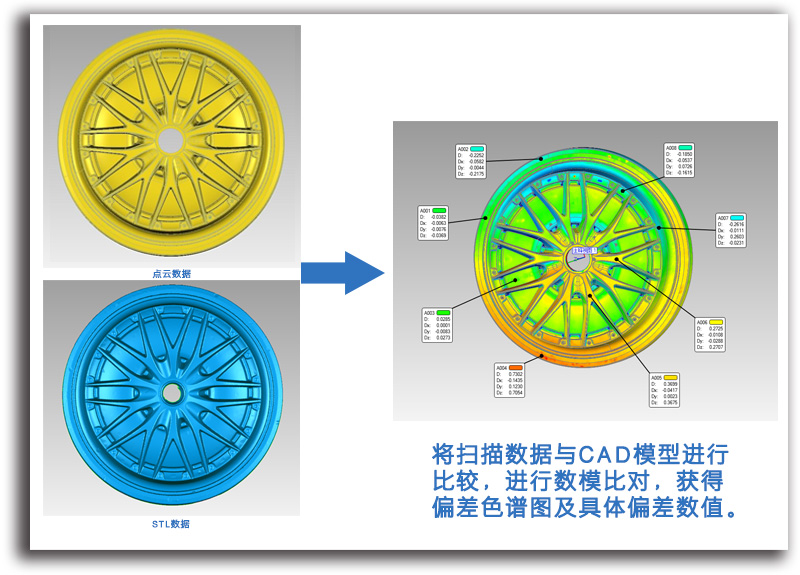

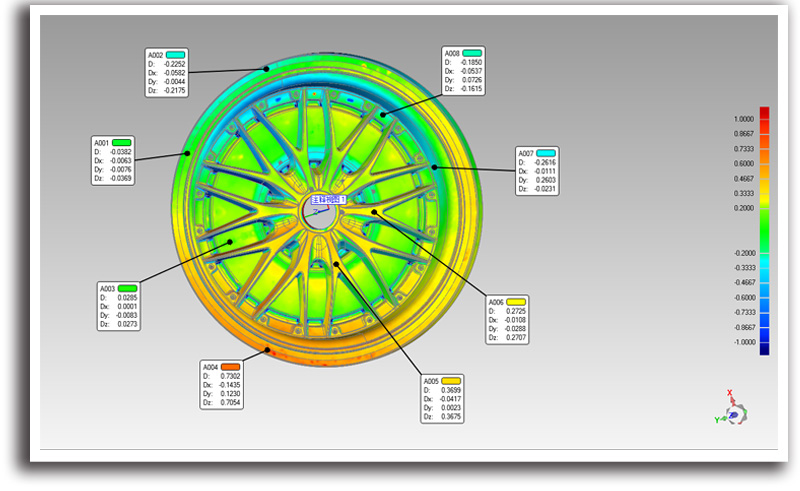

Post mark points and using HSCAN331 to scan, obtain the 3d data and then import into professional test software than do the comparison, get the report and view the deviation.

3minutes for post mark points;

4minutes for scan;

5minutes for data processing and generate test report。

Total 12 minutes

What about the result?

Comparison

Comparison with model file

Summary

HSCAN 3d scanner is easy to operate and it can scan with no death angle. Provide an efficient detection program for customer. And the equipment quality, after-sales and enthusiasm of service attitude also get users’ accept. It is convenient for customer to carry instrument to its customer for site detection.

HSCAN331

HSCAN331